Proudly engineerd in Europe

Competitively priced

Satisfaction guarantee

Future proof

On-Site Installation

Shipped worldwide

We have an industrial 3D printer for every business goal

Do you want to 3D print large parts at once or produce a lot of small parts in one print session, we make it possible. Need light weight parts that have the same strength as metal, with our Technik series printer you can make it happen.

PROTOTYPING

TOOLING

CASTING

END USE PARTS

ORTHOPEDIC

ARTS

3DBNZ printers makes your processes much faster and reduces your manufacturing cost

If you are interested in saving your organization time and money you should invest in one of our industrial 3D printers. Our customers and the business results they achieved by implementing 3D printing in their work processes are quite impressive.

Our Technik Series

Our Technik Series

Create strong and light parts

High-performance materials are stronger and more resistant than other thermoplastics, making them popular in a number of engineering applications. To 3D print such materials, you need a special printer that can handle very high temperatures. The Atlas Technik is designed for 3D printing high performance thermoplastics, which are strong and durable for long-lasting parts.

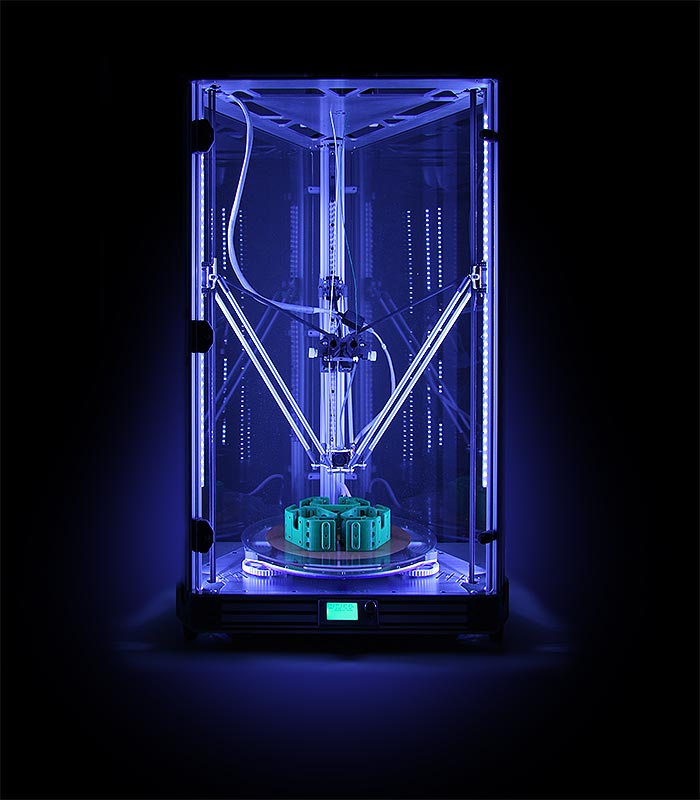

Our Large Volume Series

Our Large Volume Series

Create very large parts

The ability to use 3D printing to enhance business operations, reduce costs and improve efficiency is exactly why a 3D printer has become a popular solution. If you’re looking for a way to produce detailed and big objects our large volume 3D printers are an excellent choice. They have a much larger build size than most other industrial 3D printers and can print objects fast at high resolution.

Standalone operations

ATLAS is fully manageable through the integrated Touch LCD user

Interface, it provides a full colour graphic touch screen controller with

virtual keyboard. Also talks G-code for maximum flexibility.

The control panel can also read SD cards for printing directly from memory cards.

Ergonomy and ease of use with a single touch.

Wide range of materials

By default ATLAS hotend can reach up to 370° C, If you need to go hotter just contact us.

ADC gain calibration for thermistors allows for accurate and repeatable

temperature setting.

PC (Polycarbonate), Nylon PA66 + Carbon Fibres, ASA (Acrylonitrile styrene acrylate), ABS (Acrylonitrile butadiene styrene), HIPS (High Impact Polystyrene), PLA (Polylactide ), PLA + Wood, PETG (Glycol-modified polyethylene terephthalate)

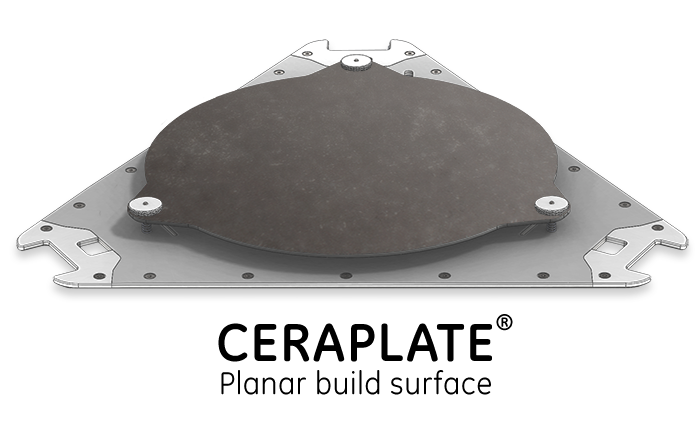

Ceramic heated build plate

From standby ATLAS reaches 120°C in few minutes.

Now with special super flat ceramic build plate !

- NEW Ceraplate build sufrace, developed for best adhesion

- Certified planarity within 0.01 mm

- Easy 3 Point leveling adjustment

The end result is a big print area with a small footprint

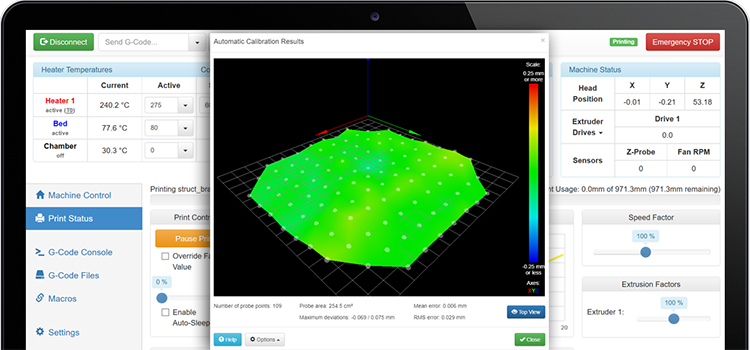

Mesh Bed Compensation

Each Atlas printers comes pre-calibrated with a mesh bed compensation file generated in our factory during the calibration phase.

We use a special Z-probe to save 109 probed points in the heat maps.

Mesh bed compensation allows the printer adjust the nozzle height during printing to compensate for any unevenness in the bed or in the geometry of the machine.

Ask other manufacturer if they have implemented this feature, we believe they didn’t.

Megatorque® extruder

The extruders on the ATLAS has a superb pulling force by using 13:1 gear reduction gearbox.

Matched with a special tooth design gear that bites the filament at constant force and drive the filament in the hot end at very precise and uniform flow.

Our test have shown we engineered the most wear resistant extruder available on the market.

Power failure resume

ATLAS is configured to allow you to resume a print after loss of power.

When the voltage drops below the threshold, the heaters are turned off to conserve power, Altas uses the energy stored in built-in capacitors to save the exact position of the printing head.

After the power is restored, the user can use the the Web Interface or the Touch screen to resume the print from where it stopped.

Fast and quiet

Our printers use UK made 32 bit state-of-the-art electronics.

You can print faster with the lowest noise emission on the market thanks to

SPI controlled Super quiet TMC2660 stepper drivers.

The printer fades into the background to provide you an undisturbed working environment. It’s now possible to work next to the ATLAS printer without being distracted.

Is all about the performance.

Technical Specifications

| ATLAS TECHNIK 4030 | ATLAS TECHNIK 4070 | |

| MECHANICS | ||

| Chassis | Aluminium | |

| Enclosure | Steel – Powder Coated RAL7035 | |

| Kinematics | Steel guide with recirculating balls / Anti backlash spherical joints | |

| Motors | Axis: Nema 23 1.8° – 9Kg-cm / Extruder: Nema 11 1.8° – 13:1 ratio | |

| Drivers | Trinamic TMC2660 | |

| Motion transmission | GT2 9 mm belt | |

| Endstops | Optical | |

| Build surface | Ceraplate ® (ceramic) | |

| DIMENSIONS | ||

| General Dimensions | 795 x 802 x 1047 mm | 795 x 802 x 1447 mm |

| Weight | 85 Kg (without flament spools) | 110 Kg (without flament spools) |

| ELECTRICAL | ||

| Input | 100-120 VAC / 200-240V 50-60Hz | |

| Energy consuption | 400W Heaters on – 71.5W Standby | |

| System voltage | 24v | |

| TEMPERATURES | ||

| Operating temperature | 15-35°C | |

| Stocking | 0-30°C | |

| Hotend | max 370° C / 400°C optional | |

| Heated bed | max 120° C / 150°C optional | |

| Hotend cooling | 30x30x10 24v fan – 5 CFM | |

| Internal electronics cooling | Thermostatic 80x80x20 24v fan | |

| INFORMATIONS | ||

| Manufacturing technology | Fused flament fabrication (FFF) | |

| Printing volume | Cylindical 400mm Ø x 300mm height | Cylindical 400mm Ø x 700mm height |

| Nozzle size | 0,4 mm (standard) 0,6 / 0,8 / 1,0 / 1,2 / available | |

| Layer height | 0,1 mm < 0,6 mm | |

| Repetability | XY: 0,1mm / Z: 0,1mm | |

| Filament diameter | 1,75 mm | |

| Compatible materials | ABS, ASA, PP, HIPS, PETG, PLA, PET, STYX-12 Nylon, TPU, Composite: Wood, Carbon, Stone, Metal | |

| Internal Storage | 4 Gb expandable to 32 Gb | |

| SOFTWARE | ||

| CPU | 32 bit | |

| Host operating system | Windows XP-7-8-10, Mac OSX, Linux | |

| Slicing Software | Simplify3D, Cura, Kisslicer, slic3r, etc. | |

| Firmware | RepRap frmware | |

| Management | Web Control Interface | |

| File format | .gcode | |

| CONNECTIVITY | ||

| LCD | 4.3” Colour LCD Touch Panel | |

| Networking | RJ45 Ethernet or 4Ghz Wif Networks | |

| USB | Type A | |

| File Transfer | SD Card / Ethernet / FTP |

We have engineered for: